Scope of Application:

The Anaerobic Chamber is a professional equipment that constructs a strict anaerobic environment with oxygen concentration ≤0.1% through a triple oxygen removal mechanism (vacuum replacement, inert gas filling, palladium-catalyzed oxygen removal). It is corely applied in anaerobic microbial culture and preservation (e.g., clinical testing, bacterial strain fermentation), biomedicine (vaccine development/antibiotic production), environmental engineering (wastewater degradation optimization), and food agriculture (cheese fermentation/soil microbial research).

Structural Features:

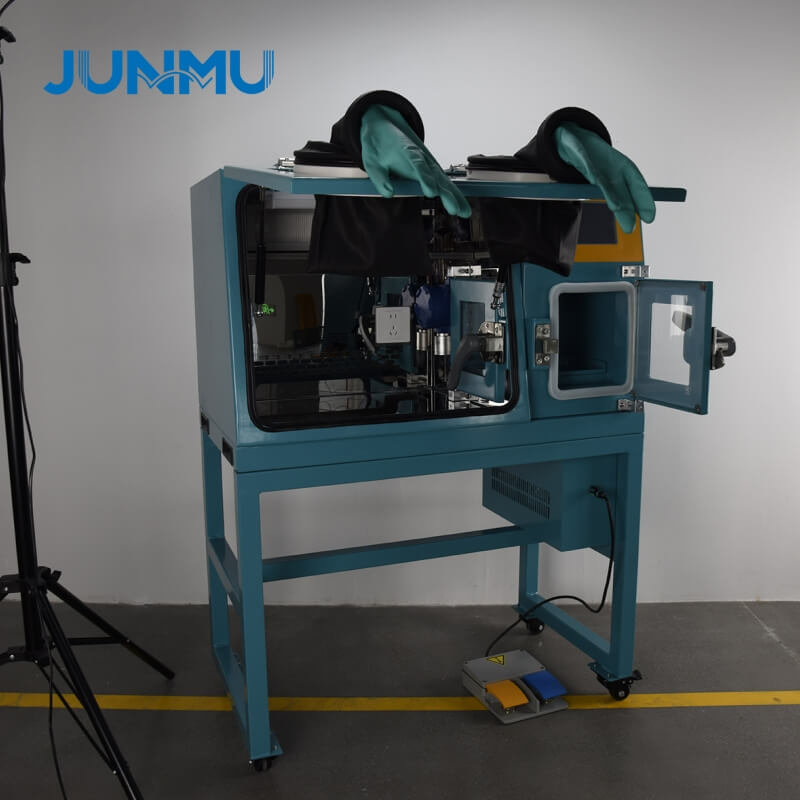

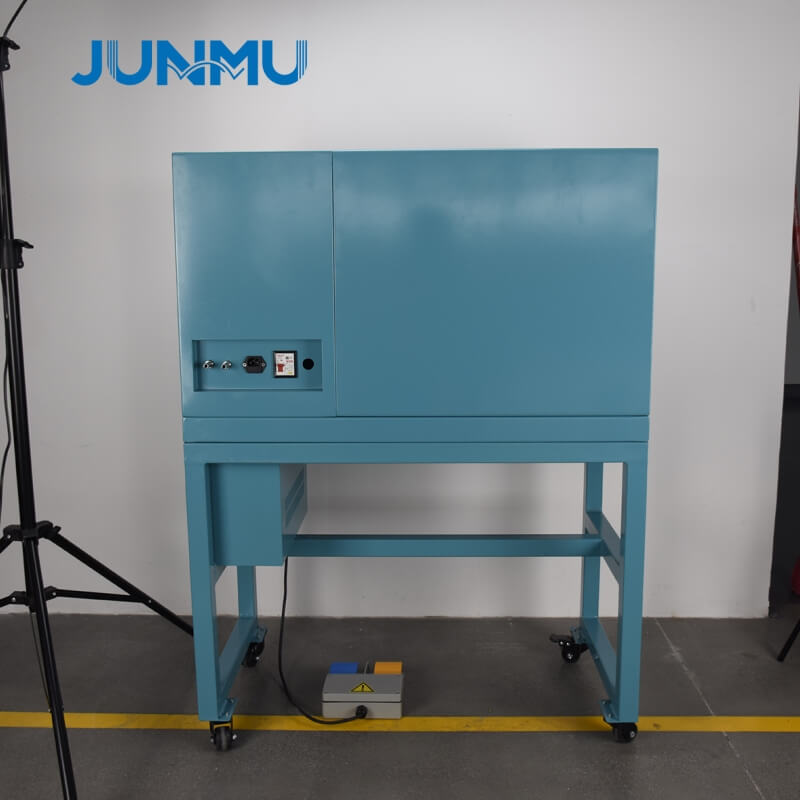

Outer Casing: Constructed from cold-rolled steel plate with electrostatic baking paint, forming a dense, robust, and rust-resistant protective layer.

Working Chamber: Suitable for anaerobic and microaerobic culture (0-10% O₂). Features a mirror-polished stainless steel interior.

★ One-key automatic gas replacement with full-auto control technology (positive/negative pressure protection).

Equipped with a low-maintenance, high-efficiency palladium oxygen removal catalyst.

Standard includes lighting, UV sterilization lamp, and power sockets.

Viewing Glass: Ultra-transparent acrylic window for clear visibility.

★ Window opens upwards for easier access and cleaning.

Sampling Chamber: Airlock chamber with automatic vacuum pumping and pressure maintenance.

★ Features one-key automatic gas replacement.

Sample Transfer: Airlock operation ensures gas exchange for samples; functions as access pathway and transfer route for petri dishes.

Sensors: Utilizes domestic high-end first-tier brands for temperature, oxygen sensors, and control modules.

Control Panel: PLC touch screen controller for accurate, intuitive control of temperature and gas concentration. Displays real-time data and operational curves.

Gas Filling/Exhaust: Dual foot pedal switch allows hands-free control for chamber filling/exhausting.

Interface: USB interface for data storage (24-month capacity).

Safety System: Includes leakage protection and an oil-free vacuum pump.

| Model | YYPC-180L-AC

YYPC-ZL-180L-AC(Refrig) |

YYPC-380L-AC

YYPC-ZL-380L-AC(Refrig) |

| Temperature Control Range | Non-refrig:RT+3~70℃ / Refrig:4~60℃ | |

| Temperature Uniformity | <±1℃ | |

| Temperature Fluctuation | <±0.3℃ | |

| Anaerobic Level | Oxygen concentration <0.1% in operation chamber | |

| Time to Achieve Anaerobic State (Sampling Chamber) | <5 minutes | |

| Method to Achieve Anaerobic State (Sampling Chamber) | Vacuum + Gas Replacement (N₂ + Mixed Gas) | |

| Time to Achieve Anaerobic State (Operation Chamber) | <50 minutes | |

| Method to Achieve Anaerobic State (Operation Chamber) | Vacuum + Gas Replacement (N₂ + Mixed Gas) + Micro-flow mixed gas replenishment and control | |

| Anaerobic Environment Maintenance Time (Operation Chamber) | >15 hours (after stopping micro mixed gas replenishment) | |

| Rated Power | 1200W(Non-refrig)

1380W(Refrig) |

1600W(Non-refrig)

1880W(Refrig) |

| Sampling Chamber Dimension WxDxH | 26x24x30cm | 30x24x30cm |

| Sampling Chamber Access Dimension WxH | 17.6×20.6cm | 17.6×20.6cm |

| Operation Chamber Dimension WxDxH | 65x48x60cm | 90x62x70cm |

| Overall Dimension WxDxH | 100x60x120cm | 140x68x137cm |